Late last year the Costume Design Center was tasked with constructing a civilian suit for George Washington interpreter Daniel Cross to wear for dance programs at the Governor’s Palace, portraying Washington before the Revolution. Today this would be considered a “semi-formal” dress suit.

To inform our design, we consulted the known record — surviving artifacts, contemporary depictions, and Washington’s papers. Clothing worn by Washington does indeed still exist, though generally from after the Revolution. Images recorded during his lifetime abound but the earliest depict only military attire. While evidence can be gleaned of his sartorial choices from the written record, an actual suit belonging to him from this period is not currently known to have survived. We decided to use an example from Colonial Williamsburg’s collection as prototype and design inspiration.

I am Melissa Mead, the Accessories Team Leader at the Costume Design Center and below, I’ll share how our staff adapted and reproduced this coat using both current and antique processes.

Beverly Prewitt, cutter, draper, and patternmaker, developed the pattern after an initial fitting with Daniel, and we adapted the fit using CAD. Next, we printed the custom pattern and selected the fabric — cream wool broadcloth (a very close match to the antique). The antique is lined with a shalloon, so we chose to line the body of the coat with a pale grey china silk which matched the silk satin waistcoat constructed to finish the white broadcloth coat and breeches.

Working with Michael Ramsey, I oversaw the execution of the embroidery design and Jenna Hallett did finishing construction on the coat, waistcoat, and breeches. We examined and studied in the original garment in the Conservation Lab, taking numerous pictures of the garment and its details to ensure accurate replication were taken.

The original silver embroidery has tarnished to black over the last 200-plus years. Polishing the embroidery could potentially damage the fabric and the metallic embroidery and is not a viable option. The Costume Design and Collections staff members were all excited at the prospect of seeing the reproduction with its gleaming silver embroidery.

The next step was to create the embroidery designs. We decided to use a combination of machine and hand embroidery to speed the process. Melissa imported the image of the design into an embroidery digitizing program and decided which parts would be done by machine and which would be done by hand. Then a sample was made to check against the original.

When content with the design, I then determined the placement of the embroidered designs. The original was embroidered only on the buttonhole side, but at the request of the intended wearer, we chose to embroider both sides.

Then, the machine embroidery was done. A base layer of stitching was done under the leaves to help give them more dimension and lines were stitched as a guide for the placement of the paillettes/spangles. After a thread change, the silver satin stitch segments were machine embroidered. Each motif took about seven minutes to stitch but trying to make sure the placement was accurate took longer.

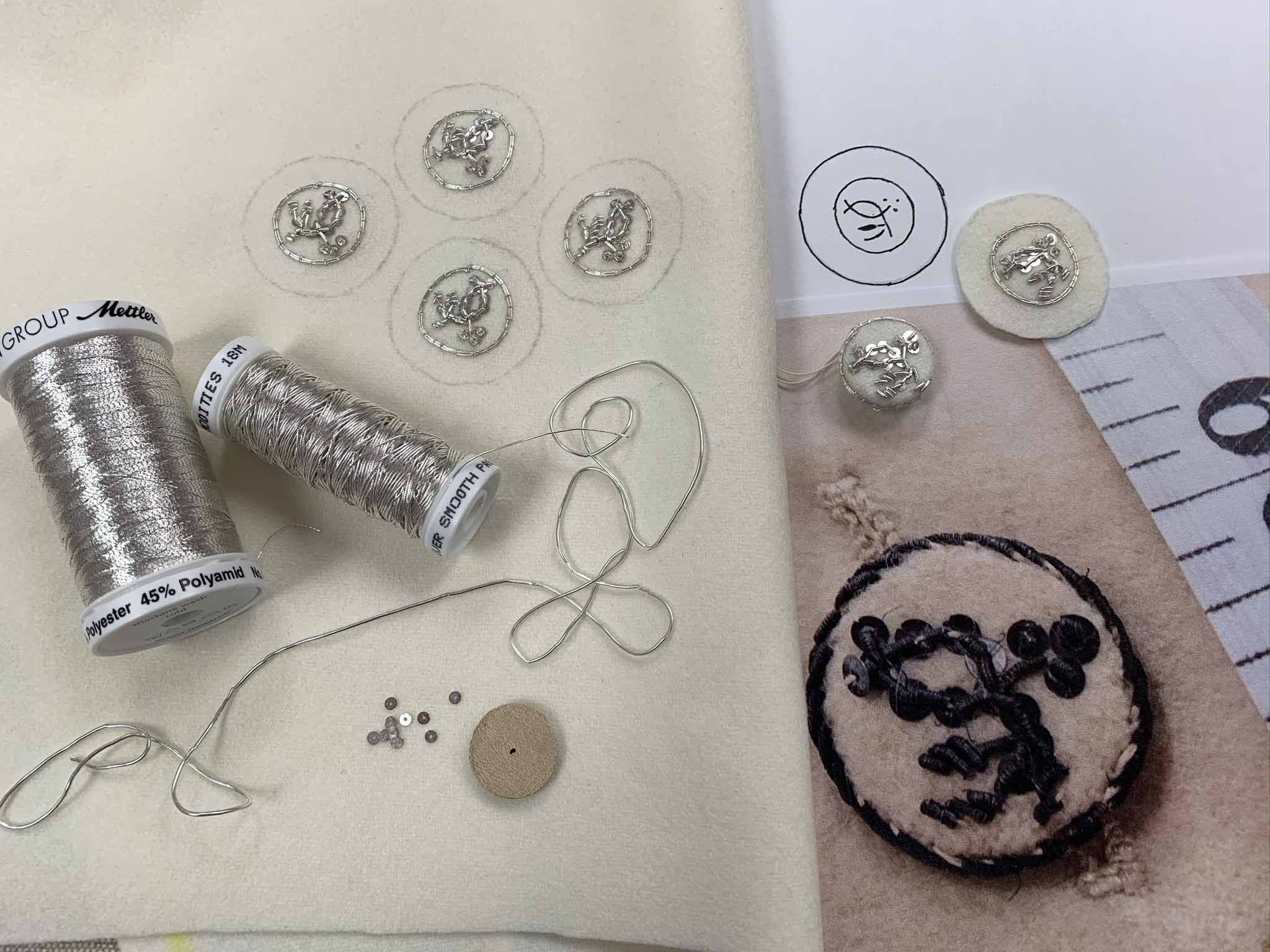

Once all the machine work was done, it was time to add the silver purl and paillettes. Purl is a spring-like coil of silver wire, which we cut to length to cover the padding stitches and to anchor the paillettes. Paillettes are sequins made of a ring of silver wire which is pounded into a flat disk with a hole in the middle.

An interesting detail of this original coat is that the embroidery spills over from the front to the top corner of the pocket flap. This means that the garment was at least partially constructed prior to being embroidered. Most often, embroidery was done prior to construction. We chose to duplicate this detail in our interpretation of the garment.

When planning this project, we debated greatly over buttons. Should we do silver metal, thread wrapped, plain fabric covered or embroidered like the original? Aesthetics and wearability were taken into consideration. In the end we decided to do embroidered buttons, but not put them down the front of the coat. The buttons are used at the top of the back vents and the knee vents of the breeches. These were entirely hand sewn.

This suit was a collaborative effort by various members of the Costume Design Center staff including Melissa Mead, Michael Ramsey, Jenna Hallett and Beverly Prewitt. It was also made possible by a very generous donation to help costume our Nation Builder interpreters.

Many thanks to Neal Hurst who let us visit the original garment several times.

Melissa Mead is the Accessories Team Leader at the Costume Design Center and has been with the foundation for nearly 17 years. She has been sewing and crafting for as long as she can remember. One of her favorite pastimes is tatting lace. She can also occasionally be seen in costume as a member of various evening programs.